VARIAC Electrical Column Variable Transformer

Rated Power: 10~300KVA

Input Voltage: 380V/400V±15%

Input frequency:50/60Hz

Output Voltage: 0-450V Adjustable

Brand: WINZPOWER

Packaging: Plywood Case

Product Introduction

TEDGZ TESGZ column voltage regulator is a dry induction voltage regulator. The three-phase column voltage regulator changes the contact position between the brush and the polished surface of the column winding to change the turns ratio of the primary and secondary windings, and finally achieves the purpose of regulation. The column electric voltage regulator is a large contact electric voltage regulator, which is a replacement product for the induction voltage regulator.

Product functions and features

The appearance, weight, volume, efficiency, waveform, operation, installation and maintenance are all better than the induction voltage regulator of the same power. It is suitable for industrial and mining power, hospitals, national defense, scientific research and other departments as a continuously adjustable test power supply. The waveform output is distortion-free and meets the power supply requirements of the IEC standard for electrical test. The output voltage is adjustable from 0 to 430V, and other voltages can be customized; its output voltage is smooth and stepless and can be adjusted under full load conditions. Reliable use, easy maintenance, strong overload capacity; it is an ideal voltage regulator equipment for on-site voltage regulation, power regulation, light regulation, and speed regulation.

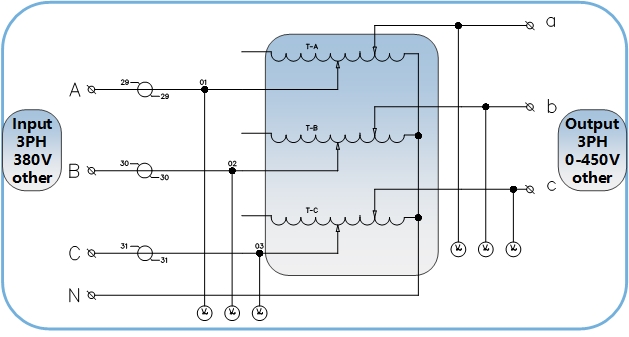

VARIAC Variable Transformer system diagram

List Of VARIAC Electrical Column Variable Transformer Technical Parameters

| Technical Parameters | ||

| No. | Technical Indicators | Content |

| 1 | Product Model | TEDGZ&TSDGZ-Series Dry-Type Isolation Transformer |

| 2 | Rated Capacity (KVA) | 10KVA-300KVA |

| 3 | Input Voltage(VAC) | Three-phase 380V&400V Single-phase 220V 110V ±10% |

| 4 | Output Voltag(VAC) | 0-450V(0-250V)Adjustable |

| 5 | System Maximum Operating Voltage(V) | 530V |

| 6 | Winding Material | All Copper Wire Wrapped Wire |

| 7 | Connection Group | VARIAC YyAuto |

| 8 | Rated Frequency(Hz) | 50/60Hz |

| 9 | Rated Phases | 3 Phases |

| 10 | Cooling Method | Temperature Control Forced Air Cooling |

| 11 | Insulation Class | H, F, B |

| 12 | Insulation Level | Power Frequency Withstand Voltage 3KV, No Breakdown and No Flashover |

| 13 | Overload Capacity | 1.5 Times Rated Current, Maintain 1 Minute |

| 14 | Display Function | Input and output voltage and current display, temperature display |

| 15 | Short-circuit impedance | <3.5% |

| 16 | No-load loss | According to standard GB1094.11-2007 |

| 17 | Load loss | According to standard GB1094.11-2007 |

| 18 | Protection level(IP Class) | IP20 Indoor, IP33 Outdoor can be customized |

| 19 | Dimensions | See the table below |

| 20 | Color | RAL7035, other colors can be customized |

| 21 | Installation location | Indoor |

| 22 | Relative humidity | 10%~90% RH |

| 23 | Altitude | Below 3000 meters Capacity derated by 10% for every 1000 meters increase in altitude |

| 24 | Ambient temperature | -25~+55℃ Maximum daily average temperature: 35℃ |

| 25 | Earthquake resistance | Ground horizontal acceleration 0.2g, vertical acceleration 0.1g |

| 26 | Use environment | The installation location is free of severe steam, chemical deposition, dust and explosives, etc. |

| 27 | Lead-in method | Transformer high and low voltage lead-in method: cable in and out from the bottom |

| 28 | Installation method | Foot-mounted fixed installation |

| 29 | Lifting method | Bottom forklift lifting |

| 30 | Noise | 55db |

| 31 | Magnetic flux density | Magnetic flux density ≤1.58T |

| 32 | Implementation standard | GB1094.11-2007 |

| Other special requirements can be communicated with winzele | ||

Application

School and industrial experiments, electrical laboratories, simulate the impact of high and low voltage output on the equipment to be tested:

Industrial heating: used for annealing furnaces, drying furnaces, heating furnaces, sintering furnaces, tunnel furnaces and other electric furnaces, adjust the voltage of the heating unit, and control the heating temperature.

Electrical transmission equipment: such as packaging machinery, injection molding machinery, heat shrink machinery, extrusion machinery, adjust the voltage of the AC motor to adjust the output speed, etc.

Glass industry: used for glass fiber, glass molding, glass melting and float glass production lines, etc.

Chemical industry: used for distillation and evaporation, preheating systems, pipeline heating, petrochemicals, etc.

Electrical equipment voltage aging test: adjust the output voltage to simulate the extreme high and low voltage of the tested electrical appliance.

Dimming: adjust the voltage of the lamps and adjust the on-site illumination, mainly used for sunlight simulation.

Aging test: servo controller development, aging test

Other industries: including salt bath furnaces, industrial frequency induction furnaces, heat treatment furnaces, diamond press heating, aviation power supply regulation, etc.

List of VARIAC Electrical Column Variable Transformer Models & Products

Single&Three-phase Model List(Their rated input voltage can be Three-phase 200V/220V/380V/440V/480V etc)

| Type |

Capacity (kVA) |

Dimension W×D×H(mm) |

| TEDGZ-10KVA | 10 | Customization |

| TEDGZ-15KVA | 15 | |

| TEDGZ-20KVA | 20 | |

| TEDGZ-30KVA | 30 | |

| TEDGZ-40KVA | 40 | |

| TEDGZ-50KVA | 50 | |

| TESGZ-10KVA | 10 | |

| TESGZ- 15KVA | 15 | |

| TESGZ-20KVA | 20 | |

| TESGZ-30KVA | 30 | |

| TESGZ-50KVA | 50 | |

| TESGZ-60KVA | 60 | |

| TESGZ-80KVA | 80 | |

| TESGZ-100KVA | 100 | |

| TESGZ-120KVA | 120 | |

| TESGZ-150KVA | 150 | |

| TESGZ-180KVA | 180 | |

| TESGZ-200KVA | 200 | |

| TESGZ-250KVA | 250 | |

| TESGZ-300KVA | 300 |

Cases and Gallery

Single-Phase VARIAC Electrical Column Variable Transformer(60KVA)

Single-Phase VARIAC Electrical Column Variable Transformer(50KVA)

Single-Phase VARIAC Electrical Column Variable Transformer(10KVA)

Three-Phase VARIAC Electrical Column Variable Transformer(50KVA)

Transformer Winding

Transformer core assembly process

Transformer Assembly Process

Transformer vacuum paint-dipping process

Transformer drying process

Temperature Rise (Heat Run) test

Test center

SBW Servo Motor Voltage Stabilizer

Three-phase Dry-type Isolation Transformer

SVC Servo Motor Voltage Stabilizer

Three Phase Split-phase Automatic Voltage Stabilizer

High-Current Dry Transformers

Static Non-contact SCR Voltage Regulator

AC Variable Frequency Power Supply

Low voltage control transformer